Catalytic Process for the production of Food grade hexane: A novel technology using clay-based catalyst developed and a commercial unit with 30000 tpa food grade hexane plant was set up at IOCL Gujarat Refinery in 1995 which was first of its kind. The unit was successfully run for several years producing food grade hexane solvent.

Cat Visbreaking process: Liquid catalyst and process for improved conversion in visbreaking units developed and implemented in Vizag refinery of HPCL resulting in 5-6% higher distillate yield and reduced cutter stock requirement in the production of fuel oil.

H2 PSA (pressure swing adsorption) Technology for hydrogen purification: H2PSA is one of the critical technologies in refineries and only two companies in the world possess this technology. Developed and set-up a 36,000 Nm3/hr 6 bed H2 PSA plant which was commissioned in 2015 at HPCL Vizag refinery. The unit is operating successfully as per the design specs. Also, adsorbent replacement was successfully done in four existing PSA units of HPCL refineries. HPCL plans to set-up new H2 PSA units in its refineries in the coming years.

CO combustion promoter catalyst additive for fluid catalytic cracker: Carbon monoxide (CO) combustion promoter additive is regularly used in FCC units in refineries. The additive was developed using spent catalyst from FCC plant and commercialised at BPCL Mumbai and Kochi refineries. This is a best example of circular economy.

HP-FurnOkare – Furnace tube descaling chemical and process for live cleaning of furnace tubes. In refineries furnaces are regularly taken offline for cleaning the furnace tube to improve heat transfer. At HPCL we developed descale chemical composition and commercialized. This is being used by HPCL refineries. Other refineries such as MRPL and IOCL are also using this chemical.

HP-COSOL – a co-solvent system for improving lube product yield. HPCL is largest lube base oil producer in India. One of the process for the production of lube oils is solvent extraction. We developed a co-solvent process and implemented at HPCL Mumbai refinery in 2015 resulting in 2wt% higher lube yield.

HP-Bioactiva: for effluent water treatment to reduce BOD, COD and phenolics. To improve the performance of effluent treatment plants, we developed a bio product called Bioactiva and commercialized at HPCL Mumbai and Vizag refineries in 2014. Subsequently this product is also being used by HMEL.

HP-DUCER: A dispersant for reducing pressure drop in fixed bed reactors. Diesel hydrotreater units face pressure drop problems often necessitating shut-down and skimming of the top layers of catalyst bed. To overcome this problem, we developed a dispersant chemical called HP-Ducer, scale-up and commercially employed at HPCL Vizag refinery. It was used for over a year in Diesel hydrotreater.

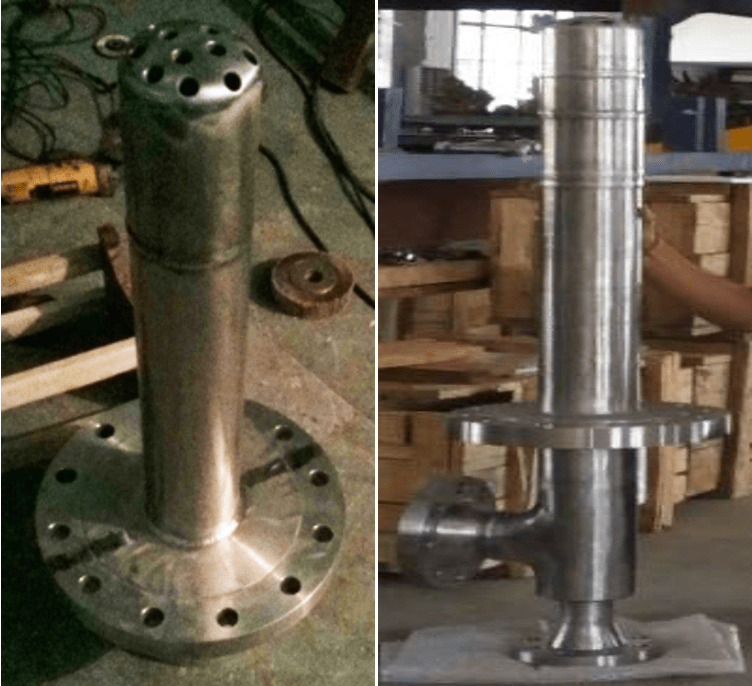

SPRAYMAX: FCC feed nozzle for better feed atomization and conversion. Feed nozzle is one the critical hardware in FCC units. One of the important functions of feed nozzle to reduce the feed droplet size reduction for better cracking. These are imported from MNCs. We at HPCL designed and developed feed nozzles and commercialized at HPCL Mumbai and Vizag refineries. These are being used since 2015.

HP-CORRMIT: Novel cost-effective corrosion inhibitor for LPG Pipelines. Developed a novel corrosion inhibitor chemical for LPG pipelines. Scaled-up and being used at MHMSPL LPG pipeline of HPCL since 2016.

HP-RAZOR: A novel additive and LPG composition for metal cutting applications. Developed an additive for LPG to enhance flame temperature to replace expensive and unsafe acetylene gas for oxy-flame applications such as metal cutting. Commercialised by HPCL and is being offered as a regular product since 2016.

HP2FCC catalyst and technology for high propylene production. Reside FCC units produce high propylene and such units required special catalyst. We developed a catalyst called HP2FCC and demonstrated at HPCL Refinery in 2017 and commercialized at HMEL in 2018. The catalyst produces 1% higher propylene.

HP-NEUTMAX: Cost effective neutralizing amine for mitigating overhead corrosion in crude units. Commercialized at HPCL Mumbai and Vizag refineries in 2017.

HP-DLA: Diesel lubricity additive for improving lubricity of BS VI diesel. Commercialized at Mumbai and Vizag refineries of HPCL and is being continuously used for the last 5 years.

HP-Bioremedia for bioremediation of oily sludge. Commercialized at HPCL Mumbai and Vizag refineries and HMEL. Being used at commercial scale for the last five years.

HP-THERMOPRO Cost effective antifoulant for crude preheat exchangers for minimizing fouling. Being used at HPCL refineries for the last four months successfully at commercial scale. Its use will be continued.

HP-DWA – Dewaxing aid for wax removal in the production Group I lube oils. Commercialized at Mumbai Refinery in 2018 and is being continuously used since then.

Corrosion inhibitor for ethanol blended gasoline. Developed a corrosion inhibitor formulation and commercialised at BPCL.

Bharat metal cutting gas (BMCG) for metal cutting applications as low cost replacement for acetylene. Developed and commercialised BMCG for metal cutting applications at BPCL which is being marketed both in India and abroad.

Special grade molecular sieve 3A for charge gas dryers. Mol sieve 3A with high coke and hydrothermal stability developed and commercialized at IPCL.

Low temp regenerable Molecular Sieve 13X for air separation plants. Mol sieve 13X which can be regenerated at low temperature developed for air separation plants and commercialized at IPCL

FCC catalyst additive for propylene maximization. Demonstrated at HPCL Vizag refinery in 2018 with about 1% higher propylene yield.

Bottoms cracking additive for FCC for the reduction of bottoms. Developed and scale-up additive to 25 tons and demonstrated at VR-FCC unit with about 1% reduction bottoms.

HP-DAK Catalytic process for Speciality solvent de-aromatised kerosene. Detailed engineering completed and construction of the grass roots plant with 52000 tons/yr capacity is in progress.

PoWer-99: High octane gasoline branded fuel for high end vehicles. Developed and launched high octane motor spirit, poWer 99 with octane rating of 99 for sports and high end vehicles. The product besides reduced knocking, also gives better fuel efficiency and lesser emissions. It is successfully launched in more than 13 cities such as Bengaluru, New Delhi, Mumbai, and Hyderabad.

HP – NEUTMAX: To mitigate overhead corrosion in crude oil units, developed a novel & cost effective neutralizing amine i.e., HP – NEUTMAX. The product was successfully demonstrated at the CDUs of HPCL Visakh refinery with better performance at lower dosages (about 25% reduction) compared to commercial products.

HP – TRAE Process: Developed an improved process called HP-TRAE for producing the environment friendly rubber process oils. TRAE-Treated Residue Aromatic extract is one of the aromatic type rubber process oil used in tyre industry. Process implemented at Mumbai. The process reduces the Poly cyclic aromatic compounds (PCA) by 0.7-0.8 wt% compared to conventional process which results in reduction of overall production cost of rubber process oil. This process also yields 2-3 wt% of more raffinate yields compared to conventional process.

Slurry hydrocracking catalyst and technology: Suitable catalyst developed for slurry hydrocracking of residue. Scale-up and demonstration at 100 ton/ann cap at HPCL Refinery planned.

Catalytic decomposition of methane to CO2 free H2: Catalyst formulation with high activity developed for the production of hydrogen and carbon nanotubes (CNTs) by catalytic decomposition of natural gas.

Hydrotreating catalyst for producing BS VI diesel: Developed a cost-effective hydrotreating catalyst for the production of BS VI diesel. The life of the catalyst is higher than commercial catalyst. Scaled-up to 2 tons. Commercial trail is expected soon at HPCL Refinery.

Solar thermic fluids: Novel formulations for medium and high temperature applications. Several formulations developed and ready for scale-up and demonstration.

Nano Lube formulations: Nano lube formulations for automotive applications developed exhibiting superior lube properties and ready for scale-up.

Novel bitumen packaging and polymer film: Developed polymer film and novel bitumen packaging process and demonstrated at BPCL Mumbai refinery.

Molecular sieve adsorbent 5A for normal paraffin separation: A novel adsorbent formulation based on molecular sieve 5A has been developed for normal paraffins separation from kerosene.

Gelator for remediation of oil spills and oil recovery: Gelators capable of selectively absorbing oil from water/ salt water developed. The gelators can absorb oil 50-150 times its weight. The oil can be easily recovered and gelator re-used.

Adsorbed natural gas (ANG) for on-board transportation applications: Adsorbent developed and suitable canister designed and demonstrated in 3-wheeler at BPCL R&D Centre.

Adsorptive separation of Light Olefin gases: Olefin selective adsorbent for the separation of light olefins/paraffin mixture developed and scaled-up to 100kg at IPCL. A 4-bed VSA process developed and demonstrated in Korea.

Catalyst and a process for Converting Light Naphtha to Aromatics: Light naphtha is a low value product in refinery. To valorise the light naphtha to high value aromatics a suitable catalyst and a process has been developed at HPCL. The catalyst is being being scale-up by HPCL team.

Catalyst for isomerization of light paraffins: For enhancing octane of light naptha, a robust catalyst which as high tolerance for impurities has been developed at HPCL.

Catalyst for the reduction of olefin content in FCC naphtha: FCC naphtha is a gasoline blend component and there is limitation on olefin content. Generally, FCC naphtha contains high concentration of olefins. A catalyst additive composition is developed to reduce the olefin content.

Counter current multistage Fischer Tropsch Reactor Systems: Developed a novel counter current multistage FT reactor system for converting coal to liquid fuels at lab scale.

Thermal swing adsorption (TSA) process for propylene drying: HPCL Mumbai refinery produces propylene which is being supplied to Andhra Petrochemcials. As moisture contents is high, a drier has been designed and developed for removing moisture to less than 10ppm from propylene product to meet the customer requirement.